How ERP Systems Improve Supply Chain Management

Introduction

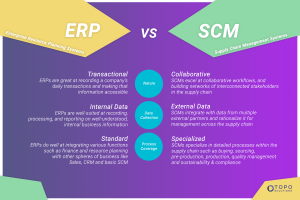

Supply Chain Management (SCM) is a crucial aspect of modern business operations, encompassing the coordination and management of all activities involved in the production and distribution of goods. Effective supply chain management ensures that products are delivered to customers efficiently, cost-effectively, and on time. Enterprise Resource Planning (ERP) systems play a pivotal role in enhancing SCM by integrating and streamlining various supply chain processes. This article explores how ERP systems improve supply chain management through improved visibility, efficiency, and decision-making.

1. Enhanced Visibility and Transparency

A. Real-Time Data Access

ERP systems provide real-time access to data across the supply chain, including inventory levels, order status, and supplier performance. This visibility allows businesses to monitor every aspect of the supply chain and make informed decisions based on up-to-date information. For example, real-time inventory tracking helps companies avoid stockouts and overstock situations by providing accurate data on current inventory levels and demand.

B. Improved Forecasting and Planning

By integrating data from various sources, ERP systems enhance forecasting accuracy and planning capabilities. ERP systems use historical data, market trends, and predictive analytics to generate more accurate demand forecasts and inventory plans. This improved forecasting helps businesses better align their supply chain activities with customer demand, reducing lead times and minimizing excess inventory.

C. Supplier and Customer Collaboration

ERP systems facilitate better collaboration with suppliers and customers by providing a centralized platform for communication and data exchange. Suppliers can access real-time information on order status, inventory levels, and forecasts, allowing them to respond more quickly to changes in demand. Similarly, customers can track their orders and receive timely updates, improving their overall experience.

2. Streamlined Processes and Efficiency

A. Automated Order Processing

ERP systems automate various supply chain processes, including order processing, inventory management, and procurement. Automation reduces manual effort, minimizes errors, and accelerates order fulfillment. For instance, when a customer places an order, the ERP system can automatically update inventory levels, generate pick lists, and trigger shipping processes, ensuring a seamless and efficient order-to-delivery cycle.

B. Optimized Inventory Management

Effective inventory management is essential for maintaining supply chain efficiency. ERP systems provide tools for real-time inventory tracking, demand planning, and replenishment. By analyzing inventory data and trends, ERP systems help businesses optimize inventory levels, reduce carrying costs, and improve stock turnover rates. Additionally, automated reorder points and alerts ensure that inventory is replenished in a timely manner.

C. Efficient Procurement and Supplier Management

ERP systems streamline procurement processes by automating purchase orders, supplier evaluations, and contract management. Businesses can track supplier performance, manage supplier relationships, and negotiate better terms based on data-driven insights. This efficiency helps reduce procurement costs, improve supplier reliability, and enhance overall supply chain performance.

3. Improved Decision-Making

A. Data-Driven Insights

ERP systems consolidate data from various supply chain functions, providing a comprehensive view of operations. Advanced analytics and reporting tools within ERP systems enable businesses to analyze key performance indicators (KPIs), identify trends, and make data-driven decisions. For example, businesses can use ERP analytics to identify bottlenecks in the supply chain, evaluate supplier performance, and optimize transportation routes.

B. Scenario Planning and Simulation

ERP systems offer scenario planning and simulation capabilities, allowing businesses to model different supply chain scenarios and assess their potential impact. By simulating various scenarios, such as changes in demand or supply disruptions, businesses can evaluate the effectiveness of different strategies and make proactive adjustments to their supply chain plans.

C. Enhanced Risk Management

Risk management is a critical aspect of supply chain management, and ERP systems help businesses identify and mitigate risks. By analyzing data on supplier performance, inventory levels, and market conditions, ERP systems can highlight potential risks and provide actionable insights for risk mitigation. For example, ERP systems can alert businesses to potential supply disruptions or quality issues, enabling them to take corrective actions before they impact operations.

4. Better Coordination and Integration

A. Cross-Functional Integration

ERP systems integrate various supply chain functions, such as procurement, production, logistics, and distribution, into a single platform. This integration ensures that all functions work with the same data and follow consistent processes, improving coordination and reducing the risk of errors or miscommunication. For instance, production schedules can be aligned with inventory levels and customer orders, ensuring that production meets demand without creating excess inventory.

B. End-to-End Visibility

End-to-end visibility is crucial for effective supply chain management, and ERP systems provide a comprehensive view of the entire supply chain. By integrating data from suppliers, manufacturers, distributors, and customers, ERP systems enable businesses to track and manage the flow of goods from raw materials to final delivery. This visibility helps identify inefficiencies, streamline processes, and enhance overall supply chain performance.

C. Seamless Integration with External Systems

ERP systems can integrate with external systems such as transportation management systems (TMS), warehouse management systems (WMS), and customer relationship management (CRM) systems. This seamless integration enhances coordination between different supply chain partners and enables more efficient information exchange. For example, integration with a TMS can optimize transportation routes and reduce shipping costs, while integration with a CRM system can improve customer service and order management.

5. Enhanced Customer Service

A. Faster Order Fulfillment

ERP systems improve order fulfillment by automating order processing, inventory management, and logistics. This automation reduces lead times and accelerates the order-to-delivery cycle, ensuring that customers receive their products quickly and efficiently. Faster order fulfillment enhances customer satisfaction and helps build stronger customer relationships.

B. Accurate Order Tracking

ERP systems provide customers with real-time order tracking and status updates. Customers can access information on order progress, shipping status, and estimated delivery times, improving transparency and communication. Accurate order tracking helps manage customer expectations and reduces the likelihood of order-related issues or disputes.

C. Personalized Customer Service

By integrating customer data from various touchpoints, ERP systems enable businesses to offer personalized customer service. For example, businesses can use ERP data to tailor promotions, recommend products based on purchase history, and address customer inquiries more effectively. Personalized service enhances the customer experience and fosters long-term loyalty.

Conclusion

ERP systems play a crucial role in improving supply chain management by enhancing visibility, streamlining processes, and supporting data-driven decision-making. Through real-time data access, automation, and end-to-end integration, ERP systems enable businesses to manage their supply chains more efficiently, reduce costs, and improve customer satisfaction. By leveraging the capabilities of ERP systems, organizations can achieve greater agility, responsiveness, and overall performance in their supply chain operations.